PRODUCT INFO

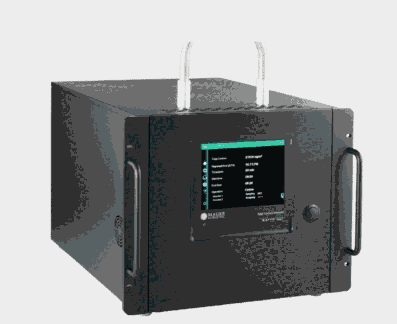

The analytical system of the Magee Scientific Total Carbon Analyzer is constructed entirely from stainless steel, making the instrument rugged, simple and reliable. The analysis uses ambient air as the carrier gas. This eliminates the need for specialty gas supplies, and greatly simplifies the installation, use, and maintenance of the instrument.

In contrast to existing bs, the TCA offers greater reliability, greater flexibility, and substantial operational cost savings for aerosol analysis.

The TCA08 can be used in online mode for continuous, real-time analysis: and offline mode to analyze previously-collected samples..

ADVANTAGES AND BENEFITS

CONTINUOUS OPERATION

The timebase for sampling and analysis is adjustable from 20 minutes to 24 hours.

NO GAS, NO GLASS

Ambient air is used as the analytical carrier gas at a very low flow rate. This eliminates the need for specialized gas supplies.

The analytical chambers are made of stainless steel: the instrument contains no fragile glass components.

OC/EC DETERMINATION

The Total Carbon Analyzer provides the result for TC.

Since {TC = OC + EC}, it follows that {OC = TC – EC}.

The Total Carbon Analyzer may be connected to a Model AE33 Aethalometer, which provides real-time data for BC, closely related to ‘EC’. The Aethalometer data is automatically combined with the TCA data to provide a full characterization of the carbonaceous component of the aerosol in near-real-time: TC, OC, BC (or ‘EC’).

CONTINUOUS OPERATION

One channel collects the sample, while the second parallel channel is being analyzed. Ball valves automatically switch between the two, every timebase period, to provide continuous operation.

QUICK INSTALLATION, AUTOMATIC OPERATION

The instrument can be installed quickly with no specialized resources required. It operates automatically and recovers from power interruptions.

OC/EC DETERMINATION

Carbonaceous matter {TC = OC + EC} is often the largest contributor to PM2.5 mass. The Total Carbon Analyzer provides the result for TC.

Since {TC = OC + EC}, it follows that {OC = TC – EC}.

The Magee Scientific Total Carbon Analyzer may be connected to a Model AE33 Aethalometer, which provides real-time data for BC, closely related to ‘EC’. The Aethalometer data is automatically combined with the TCA data to provide a full characterization of the carbonaceous component of the aerosol in near-real-time: TC, OC, BC (or ‘EC’).

This is accomplished in a rugged, reliable instrument package that is suitable for laboratory, fieldwork, and routine Air Quality monitoring applications.

RUGGED INSTRUMENT

The Magee Scientific Total Carbon Analyzer Model TCA08 is constructed in a rugged instrument package suitable for laboratory, field-work and routine Air Quality monitoring applications.

MEASUREMENT PRINCIPLE

The Magee Scientific Total Carbon Analyzer collects a sample of atmospheric aerosols on a quartz fiber filter enclosed in a small stainless-steel chamber, at a controlled sampling flow rate of 16.7 LPM. The default sampling time is 60 minutes, but may be set from 20 minutes to 24 hours depending on the ambient aerosol concentrations.

The instrument has two identical parallel channels, with the air flows being controlled by ball valves and solenoids. While one channel is collecting its sample, the other channel is analyzing the sample collected during the previous period. At the end of the period, the valves switch over to provide continuous operation and continuous data.

After collection on the filter, two flash-heating elements combust the sample instantaneously in a small ‘analytic’ flow of filtered ambient air. This converts all the carbonaceous compounds into CO2, and creates a short but large-amplitude pulse of CO2 in the analytic flow passed to the NDIR CO2 detector. The background level of CO2 in ambient air during the heating cycle is determined before and after the heating cycle, the provide the baselines against which the combustion pulse is measured. The CO2 concentration over the baseline is integrated to give the Total Carbon content of the sample.

The chamber and combustion elements are cooled after analysis. At the end of the timebase period the flow system of ball valves and solenoids switches over. The first channel collects the next period’s sample, while the second channel is analyzed.

SPECIFICATIONS

OPERATION

Supply voltage: 100-240 V~, 50/60 Hz

Max power consumption: 600 W (Heaters 400 W, Sample pump 100 W, Analytic flow pump 25 W)

Airflow: Sample Airflow 16.7 LPM, Analytic Airflow 0.5 LPM

Time resolution: 60 min (default); user-selectable 20 min to 24 hours

ENVIRONMENTAL OPERATING CONDITIONS

Indoor use, rack or benchtop (instrument)

Altitude: up to 3000 m

Temperature range: 10 – 40 degrees Celsius (instrument)

Relative humidity range: non-condensing

ANALYTICAL PERFORMANCE

Sensitivity: 0.5 μg C/m3 at 60 min Sample time base and 16.7 LPM Sample Airflow

MECHANICAL SPECIFICATION

Chassis: standard 19’’/9U, rack mount, constructed of sheet bl

Inlet plumbing requirement: the minimum overall height of the Total Carbon Analyzer (TCA) chassis and inlet tubing is 1.20 m. See Figure 1.

Weight: 35 kg

CONNECTORS

Sampling air stream:

l inlet: inner diameter 14 mm, outer diameter 18 mm, custom connectors. See Figure 2.

outlet: .1/4” NTPF

Analytic air stream:

l inlet: 1/8’’’ NTPF

outlet: (internal, not brought to panel connector)

Communications:

l 6x COM, 4x USB 2.0, 1x USB 3.0, 3x power USB, Ethernet

USER INTERFACE

l 8.4” SVGA display with LED backlight

l Basic control: touch-screen

l Optional control: standard PC keyboard and mouse

l Red, Yellow, Green status LEDs